Impact of Deep Learning on Solar Panel Defect Detection

- April 4, 2024

- Prescinto

One of the key aspects of solar PV maintenance is regular inspection to detect any defects or issues that could affect their efficiency. Traditional inspection methods have their limitations, often requiring significant time and resources. However, with the advent of deep learning technology, a new era of solar panel inspection has dawned. Deep learning algorithms are transforming defect detection in solar panels, making inspections faster, more accurate, and more cost-effective.

Deep learning has high-impact use cases in the rapidly growing solar energy industry. The solar energy industry has experienced remarkable growth in recent years, with an increasing number of solar plants installed worldwide. Anticipated data from the International Energy Agency (IEA) indicates a significant surge in solar energy capacity, with projections reaching 1.5 terawatts (TW) by the year 2025. This signifies a remarkable growth of 150% from the 603 gigawatts (GW) recorded in 2019. The promising trajectory of solar projects reflects a substantial expansion in the global solar energy landscape, paving the way for a more sustainable and resilient future.

Utility-scale solar plants are composed of thousands of panels, each susceptible to potential defects arising from mishandling and improper installation. A utility-scale solar power plant typically requires between 5 and 10 acres of land per megawatt (MW) of generating capacity, according to the Solar Energy Industries Association. This makes manual monitoring of panels costly and time-consuming, and plants situated in remote locations pose additional challenges for human access. Ensuring the efficient operation of these solar plants is of utmost importance, as any defects or anomalies can lead to energy loss.

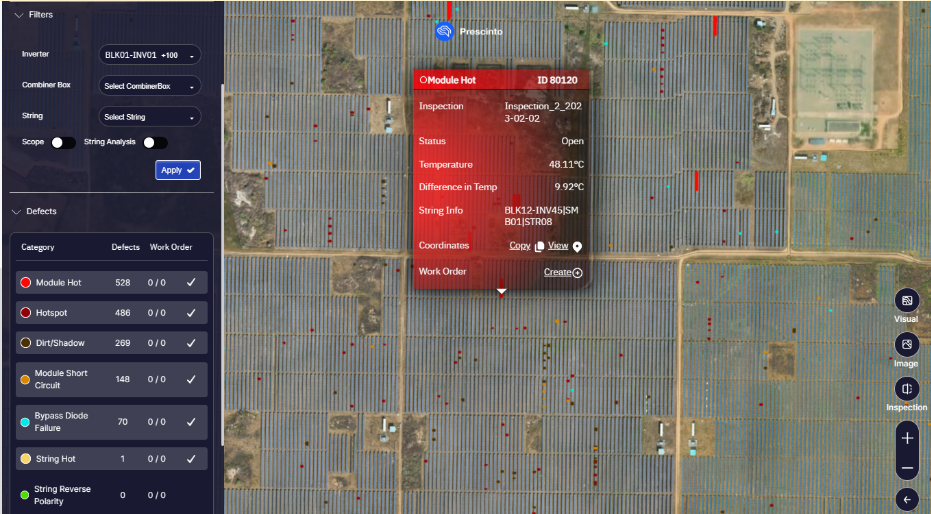

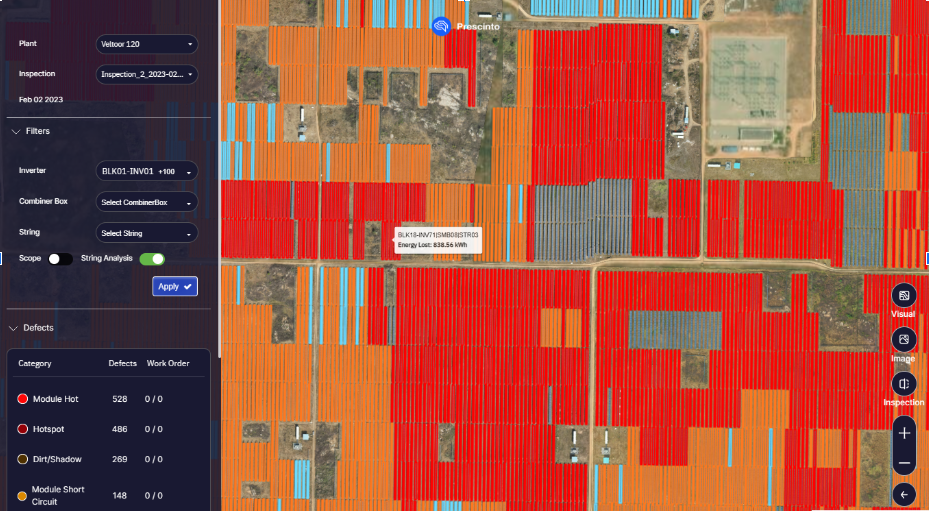

Prescinto’s Drone View addresses this concern by integrating drone thermography data and state-of-the-art object detection algorithms to identify defects in solar panels. Combining this with the string analysis capabilities helps generate precise insights and quantifies estimated losses due to these defects.

How Does Prescinto Conduct Thermal Imaging and Analysis?

Thermal imaging and analysis is a multi-step process involving third-party drone vendors to capture thermal and visual raw images and use them to create monolithic visual orthomosaic and inferno orthomosaic.

This is followed by an object detection algorithm to identify and classify the defects. Once the defects are identified, the images are superimposed with a table structure to identify the tables and strings and then the defects are mapped to each table using the geo-coordinates from the image.

How Does Prescinto’s Deep Learning Defect Detection Model Work?

Prescinto’s defect detection model is trained on the following data:

-

Inferno Orthomosaic

Inferno orthomosaics are radiometric images of the solar plant, capturing temperature variations. The orthomosaic is a composite image, often generated using photogrammetry techniques to stitch together multiple images.

-

Defect XMLs

Defect XML files contain information about defects and their locations. Each XML includes details like the type of defect and the bounding box coordinates (xmin, ymin, xmax, and ymax). Annotations are done using CVAT.

-

Annotated Defect Images

Annotated defect images serve as visual references for each defect type. These images help in training and validating Prescinto’s defect detection model. Prescinto is agnostic to any specific drone platform. It can ingest and process drone thermal images from any third-party drone imaging vendors provided they meet Prescinto’s image-analysis standards.

3 Ways to Utilize Prescinto’s Deep Learning and Drone Analytics

Prescinto’s Drone Analytics, powered by deep learning AI, enables precise defect detection in solar panels. This technology streamlines maintenance planning, ensuring optimal plant performance and longevity. Here are three crucial ways to leverage Prescinto’s Drone Analytics and deep learning models for efficient defect detection and maintenance planning in solar plants.

-

Defect Detection

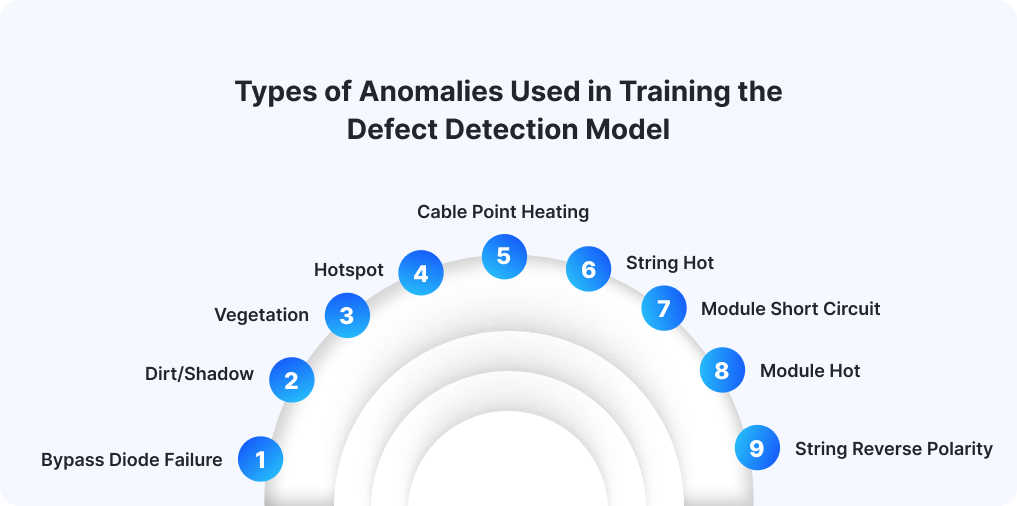

If undetected, the cumulative losses of solar panel defects can significantly impact generation numbers. Therefore, the defect detection model based on deep learning AI is trained on a range of defects.

-

Drone with String Analytics

Traditional drone analytics only detect the anomalies and don’t quantify the estimated losses. Precinto’s unique capabilities of combining drone analytics with string analysis help operators leverage the insights of estimated losses due to defects. This helps in planning and prioritizing the remedial actions based on generation impact.

-

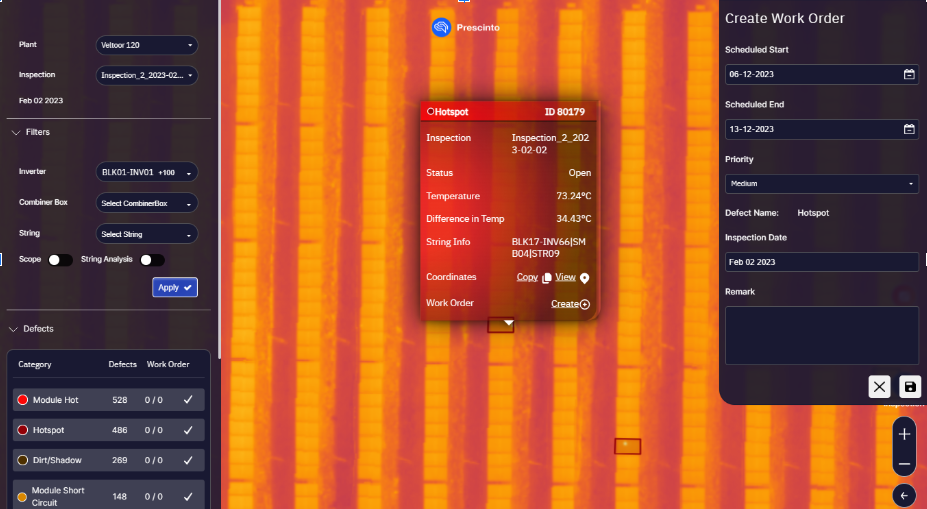

CMMS Integration

The remedial/corrective actions must be planned and performed as per the schedule set by site engineers. To make it seamless, Prescinto’s platform provides the capability to create work order tickets directly from the drone analytics page. This integration simplifies the workflow for site engineers, allowing them to quickly generate work orders based on insights gathered from drone analytics. This streamlined process eliminates the need for manual intervention, reducing the risk of errors and delays. Furthermore, operators can check historical inspection data and compare the changes in defects. Prescinto’s platform ensures that maintenance tasks are carried out promptly and efficiently, by enabling direct action from analysis to execution.

Advantages of Combining Drone Analytics and Deep Learning

- Improving Operational Efficiency at Solar Plants

Solar plants cover extensive areas, and identifying temperature-related defects visually can be challenging. However, with the implementation of deep learning and object detection techniques, site engineers can swiftly and accurately locate these defects. This technological advancement reduces the need for manual inspections, saving time and effort for engineers. By swiftly and accurately identifying temperature-related defects, site engineers can address issues promptly. This minimizes downtime and reduces Mean Time to Repair (MTTR). Additionally, the proactive approach to defect detection helps in preventing failures, thereby increasing the Mean Time Between Failures (MTBF) of the equipment. This ultimately leads to improved overall plant efficiency and performance.

-

Optimizing Operational Expenses (OpEx)

Automation significantly reduces the labor and time required for inspection, leading to substantial cost savings for solar plant operators. By streamlining the inspection process, automation reduces operational expenses (OpEx) associated with manual labor and allows for more efficient use of resources. This, in turn, positively impacts the bottom line of solar plants by increasing profitability. Additionally, automation helps in identifying defects early, preventing costly repairs, and minimizing downtime, further contributing to improved financial performance.

-

Deploying Proactive Anomaly Detection

Early detection of defects through the use of drone imagery and deep learning model significantly impacts the asset lifecycle and extends asset life in solar installations. By identifying defects early, extensive damage causing potential issues can be promptly addressed. This can prevent energy loss and minimizes the need for costly repairs. This proactive approach ensures optimal performance throughout the plant’s lifecycle, leading to improved efficiency, reduced downtime, and increased energy production. This ultimately extending the lifespan of the solar panels and the entire plant.

Accelerating the transition to renewable energy is paramount, and reducing the Levelized Cost of Energy (LCOE) in the solar industry is key to achieving this goal. The adoption of innovative technologies, such as a combination of drone imagery and defect detection model, is instrumental in achieving this objective. Solar plants require meticulous construction and maintenance oversight, including regular technical inspections and security provisions, to ensure optimal performance. Although the capital expenditure per megawatt (MW) has decreased significantly over the years, operational costs remain high.

The integration of drone imagery and deep learning models presents an efficient and precise solution for detecting defects in solar panels. This technology not only simplifies the inspection process but also guarantees the optimal performance of solar plants. This fosters the broader adoption of renewable energy sources. By reducing the LCOE and enhancing overall solar energy accessibility, drone analytics play a crucial role in expediting the global shift toward sustainable energy solutions.

- Topics: Deep Learning, Solar

About Author