Unlocking Efficiency: Managing Renewable Energy’s Work Orders

- April 26, 2024

- Prescinto

Unlocking Efficiency: Managing Renewable Energy’s Work Orders

Work order management in renewable energy operations and maintenance (O&M) encompasses a dynamic balance between planned and unplanned activities, each serving a critical role in the effective operation of renewable energy systems.

For renewable energy plants, planned activities, often regarded as the backbone of maintenance strategies, are meticulously scheduled in advance to preemptively address potential issues and optimize equipment performance. These proactive measures encompass routine inspections, preventive maintenance tasks, and component replacements. These measures are strategically orchestrated based on factors such as manufacturer recommendations, historical equipment data, and usage patterns.

By adhering to a well-defined schedule of planned activities, renewable energy plant operators can detect and rectify minor issues before they escalate into major problems, thus minimizing the risk of unexpected downtime and maximizing the overall reliability of the system.

The Digital Transformation Playbook for Renewable Energy O&M – Download Now

In contrast, unplanned activities represent the reactive response to unforeseen equipment failures or malfunctions that demand immediate attention. These unexpected events, ranging from sudden breakdowns to sensor alarms indicating abnormal operating conditions, necessitate swift and decisive action to restore equipment functionality and mitigate potential disruptions to energy production.

Unplanned activities encompass emergency repairs, fault diagnosis, troubleshooting, and expedited equipment replacements. These activities are geared toward swiftly addressing the underlying issue and minimizing the impact on system performance.

While planned activities offer a proactive approach to maintenance, aimed at preemptively addressing potential issues, unplanned activities serve as a rapid response mechanism to unforeseen challenges, ensuring the prompt restoration of equipment functionality. By striking a harmonious balance between these two facets of work order management, renewable energy operators can optimize system reliability, minimize downtime, and maximize energy production, thereby bolstering the overall efficiency and longevity of their renewable energy assets.

Constraints in Advancing Renewable Energy Deployment

Analyzing and generating corrective work orders for ever-increasing capacity presents a significant challenge in renewable energy management. As systems expand, the complexity of identifying and addressing issues grows exponentially.

This complexity stems from the need to accurately diagnose problems, allocate resources efficiently, and minimize downtime while maintaining optimal performance.

Furthermore, with larger capacities, there’s a higher likelihood of encountering diverse and interconnected issues, requiring a nuanced approach to prioritize corrective actions. Thus, navigating this challenge demands advanced analytics and streamlined workflows to ensure the effective management of renewable energy plants.

Maximizing Effectiveness: The Urgency of Automating Work Order Generation

The need for automating work order generation and management in renewable energy systems is becoming increasingly apparent due to the growing scale and complexity of these systems. With manual methods struggling to keep pace with the volume and velocity of data generated, there’s a pressing demand for more efficient operations and maintenance practices.

Automation, powered by technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), offers a solution. By harnessing smart sensors and AI algorithms, automation enables real-time detection of anomalies and potential failures. This proactive and predictive maintenance approach allows for swift response and prioritization of work orders based on criticality and resource availability.

Implementing automation optimizes resource allocation, minimizes downtime, and enables organizations to refine maintenance strategies over time. The result is improved operational efficiency, reduced maintenance costs, and enhanced system reliability. In the dynamic renewable energy sector, automation is crucial for achieving sustained growth and performance.

Breaking Barriers: 3 Primary Challenges in Automating Work Order Processes

Challenges in automating work orders arise from limited context awareness, momentary signal issues, and inflexible configuration options. Overcoming these demands a deeper understanding of system dynamics, strong data validation, and adaptable tools for asset managers.

1. Limited Context Awareness

One significant challenge in automating work orders is the lack of comprehensive context awareness. Many automation logics provided by various tools focus solely on individual devices without considering the broader operating conditions or the interdependencies among devices. As a result, these strategies often generate inaccurate alerts and alarms, leading to the issuance of unnecessary work orders. Without a holistic understanding of the system’s overall health and the potential impact of one device’s condition on others, automation efforts can be hindered by false alarms and ineffective work order generation.

2.Momentary Signal Issues

Another obstacle to successful automation is the occurrence of momentary signal issues and inconsistent data flow within the system. Fluctuations in signal strength or data transmission can trigger erroneous actions by automated systems, resulting in false alarms or unnecessary work orders.

These momentary signal issues may arise due to various factors such as environmental conditions, electromagnetic interference, or temporary network disruptions. Addressing these challenges requires robust data validation mechanisms and signal-filtering techniques to distinguish genuine anomalies from transient fluctuations.

3. Lack of Configuration Flexibility

Many automation tools offer fixed methods for monitoring and generating work orders, limiting the flexibility of asset managers to configure monitoring strategies according to their specific needs and preferences. This lack of customization options can hinder the effectiveness of automated systems, as asset managers may have insights or domain knowledge that are not accommodated by rigid automation frameworks.

Providing asset managers with greater flexibility to tailor and refine automated monitoring strategies based on their expertise can enhance the accuracy and relevance of generated work orders.

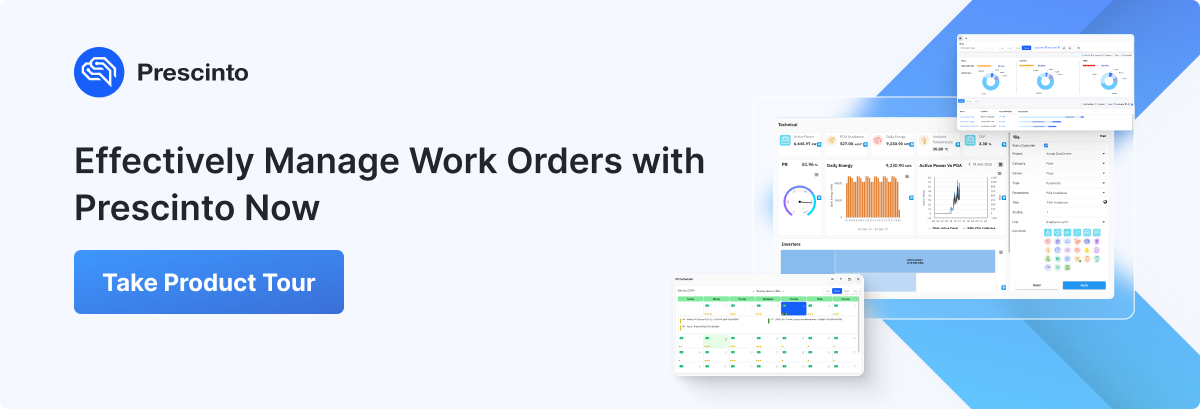

How Prescinto’s Simplifies Automation Challenges

Prescinto offers a comprehensive solution to automate work orders in renewable energy management, addressing key challenges faced by O&M and asset managers. One significant challenge in automating work orders is the lack of comprehensive context awareness.

Most automation logics provided by various tools focus solely on individual devices without considering the broader operating conditions or the interdependencies among devices. This often leads to inaccurate alerts and alarms, resulting in unnecessary work orders. Prescinto, however, provides a holistic view of system conditions, ensuring accurate anomaly detection and precise work order generation based on device interdependencies.

Another obstacle to successful automation is the occurrence of momentary signal issues and inconsistent data flow within the system. Fluctuations in signal strength or data transmission can trigger erroneous actions by automated systems, resulting in false alarms or unnecessary work orders.

Prescinto’s intelligent algorithms filter out transient fluctuations, minimizing false alarms and ensuring that maintenance efforts are focused on genuine issues. This robust data validation mechanism addresses momentary signal issues effectively, regardless of the underlying factors causing them.

Furthermore, many automation tools offer fixed methods for monitoring and generating work orders, limiting the flexibility of asset managers to configure monitoring strategies according to their specific needs and preferences. This lack of customization options can hinder the effectiveness of automated systems.

However, Prescinto offers customizable monitoring parameters, empowering asset managers to tailor strategies to their needs and optimize maintenance efforts. By providing asset managers with greater flexibility, Prescinto enhances the accuracy and relevance of generated work orders, ensuring that they align with the organization’s objectives and operational requirements.

- Topics: Work Order

About Author