3 Digitization Strategies to Improve Profitability in the Wind Energy Industry

- February 4, 2024

- Prescinto

The wind energy industry is facing a major profitability challenge that requires innovative solutions. As renewable energy sources like wind power continue to play a vital role in our global energy transition, optimizing profitability becomes paramount. Factors such as operational efficiency, maintenance costs, and energy production variability pose significant hurdles.

In 2022, wind power generation witnessed a remarkable surge, recording an unprecedented increase of 265 terawatt-hours (TWh), as per the International Energy Association. It recorded a 14% increase in generation, reaching a total of over 2,100 TWh. However, in the same year, several major wind energy firms reported billions in losses due to a plethora of challenges that have made it harder to develop new wind farms worldwide, as reported by Yahoo Finance.

To address these challenges, the industry is increasingly turning to cutting-edge technologies like artificial intelligence and advanced analytics and monitoring systems to enhance wind farm performance and profitability. With advanced technologies, the industry can improve the maintenance, optimization, management, and operations of its turbines to achieve greater efficiency and cost savings. Let’s discuss the top three ways in which AI is helping to fix the profitability problem in the wind energy industry.

Overview of the profitability problem in wind power generation

The wind energy industry is rapidly growing, but it is not without its challenges. Price volatility, weather conditions, and other external factors make the operation of wind turbines unpredictable and volatile. Additionally, installation and maintenance costs are high, efficiency losses during operation can reduce profitability, and the need for large amounts of land for turbine deployment can limit growth potential.

These issues have become increasingly pronounced over time as the industry seeks to increase its cost competitiveness with traditional sources of energy such as oil and gas. To remain profitable in this challenging landscape, the industry must find innovative solutions to address these issues. Advanced technologies, including artificial intelligence (AI), machine learning (ML), and advanced data analytics, are emerging as powerful tools for tackling these problems head-on – allowing for greater efficiency and cost savings in wind energy operations, ultimately helping wind power-generating companies become more competitive and profitable in today’s challenging market environment.

Monitoring wind energy operations

AI-driven asset performance management (APM) solutions can continuously monitor turbine performance, detect latent underperformance issues, and alert technicians when repairs are needed. This allows for proactive maintenance that reduces downtime, saves time and money, and prevents costly breakdowns. Additionally, AI can optimize repair processes by providing technicians with data-driven recommendations on how to fix any issues that have been detected. This streamlines the process of fixing problems while ensuring that all repairs are done correctly.

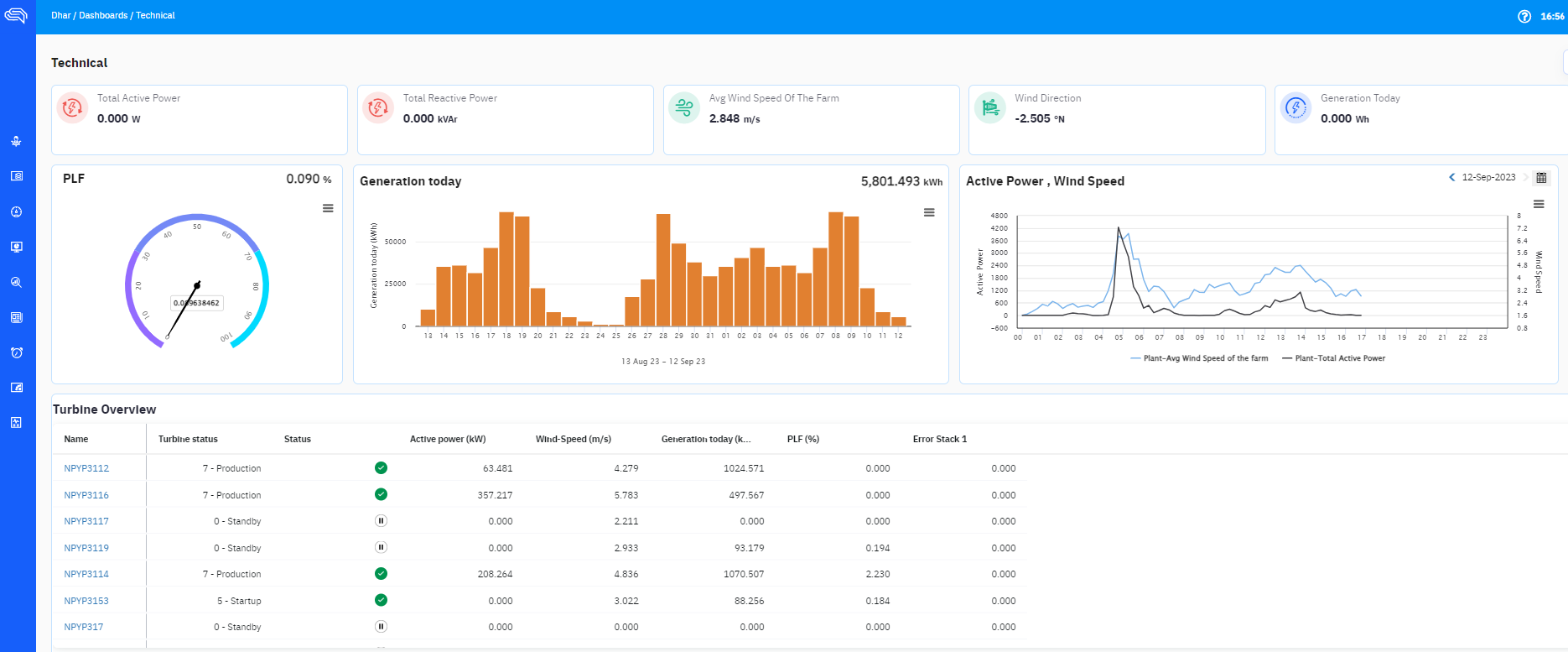

Prescinto’s wind energy asset performance management (APM) platform offers a comprehensive solution for live monitoring across various levels of hierarchy, providing users with a detailed view of their wind energy operations. This monitoring extends across the entire wind energy plant, individual turbines, and specific components such as nacelle, rotor, gearbox, generator, and more. With high-definition map views and real-time data, users can gain invaluable insights into the performance of each element, enabling proactive maintenance, optimization, and improved overall operational efficiency.

Prescinto’s advanced features empower wind energy operators with in-depth insights and analysis capabilities. With turbine-to-turbine analysis, users can effortlessly compare power curves for all turbines within a single window, making it easy to identify outliers and performance variations. Additionally, Prescinto‘s platform allows users to assess rotor and gearbox efficiency by measuring the influence of factors, such as turbulence and aerodynamic imbalances, which can impact energy conversion efficiency. This helps operators better understand how their turbines are performing and make informed decisions about how to improve efficiency or reduce costs. Thus, the wind energy industry can become more efficient and cost-effective while maintaining a high level of safety standards.

Turbine optimization and management

By leveraging powerful algorithms, asset owners can monitor their wind turbines more precisely and detect potential problems before they become serious. This allows for greater efficiency and better resource utilization, resulting in cost savings while reducing environmental impact. Additionally, automated solutions can be used to schedule maintenance tasks more wisely. All this helps wind energy asset owners increase profits while providing a reliable source of renewable energy to the global market.

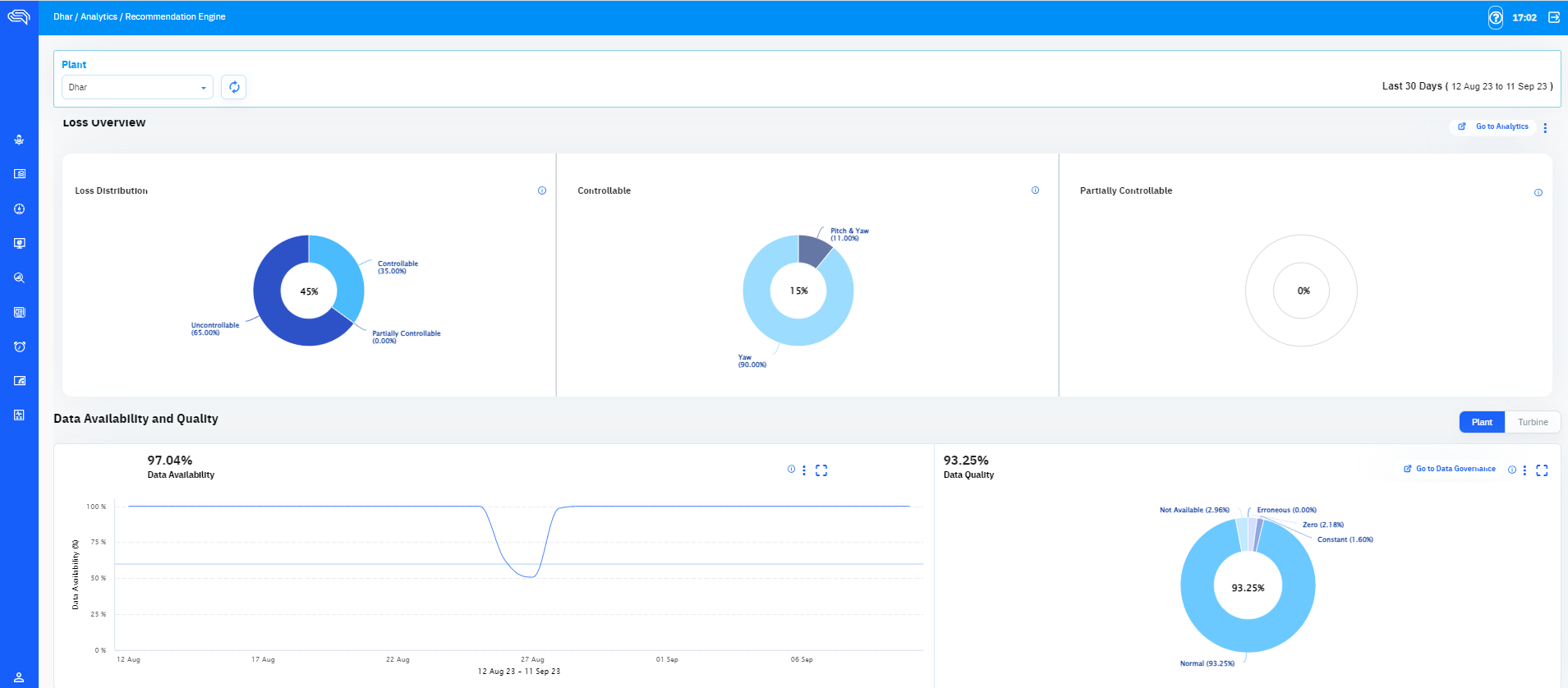

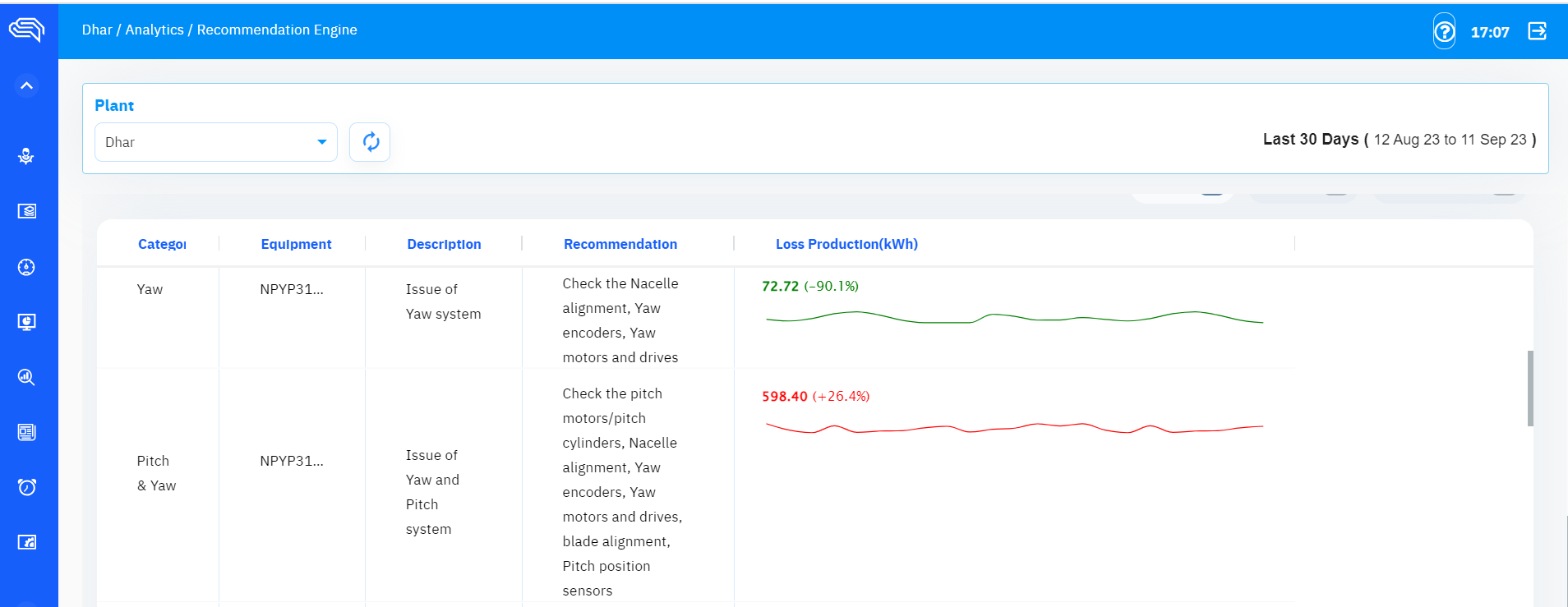

Prescinto’s AI-powered platform offers 360° visibility into all types of wind power generation losses, including controllable (gearbox or bearing damage, yaw misalignment, etc.), partially controllable (yaw untwist, icing, etc.), and uncontrollable losses (high temperature, low or fluctuating wind speeds, etc.). The platform features an AI-driven recommendation engine that not only identifies the root causes of underperformance but also delivers precise actionable insights. This enables immediate course correction, ensuring that wind power facilities can optimize their performance and maintain consistent energy production levels.

Wind turbine operations improvements

The wind energy industry is undergoing a revolution with the emergence of AI technologies. By leveraging advanced algorithms and analytics, companies can optimize turbine deployment, anticipate potential maintenance issues, and increase the accuracy of forecasting and scheduling tasks. This improves the efficiency of operations while reducing costs. Additionally, AI-driven monitoring systems can detect performance issues in real time to allow for corrective action without delay, while machine learning (ML) algorithms can help optimize energy capture despite ever-changing external conditions.

Prescinto’s platform assists operators in determining strategies for inconsistent pitch, effectively identifying and addressing inefficiencies resulting from variations in wind turbine pitching. Moreover, it excels in faulty sensor detection, efficiently recognizing and rectifying issues with anemometers or wind vanes that may otherwise lead to misleading insights during power curve analysis. With these features, Prescinto ensures accurate data-driven decision-making, improving overall operational efficiency and energy production across wind energy assets.

Prescinto enables yaw misalignment detection, through which the platform effectively identifies and addresses consistent deviations between wind direction and nacelle position, optimizing turbine performance. Furthermore, its power curve analysis, compliant with IEC 61400-12 standards, provides in-depth insights into turbine performance and generation losses. By offering loss buckets, it allows operators to pinpoint the exact causes of underperformance, enabling precise corrective actions and ensuring maximum energy generation efficiency.

Wind energy’s technology path to profitability

APM solutions powered by advanced technologies, such as AI/ML and advanced data analytics, provide wind energy asset owners with an unparalleled opportunity to become more profitable while providing reliable renewable energy sources. Through improved control over data and performance analysis, asset owners can better plan for future tasks and reduce downtime caused by potential maintenance issues or unexpected weather changes. Moreover, the integration of advanced technologies into monitoring systems ensures that any performance issues are identified quickly and dealt with swiftly – allowing for cost savings as well as higher quality standards of service.

Advanced APM solutions optimize wind power facilities’ performance and maintain a steady flow of energy production, which directly translates into increased revenue. These solutions enable precise corrective actions, minimizing downtime and ensuring turbines operate at maximum energy generation efficiency, thereby reducing operational costs. Moreover, by streamlining operations and maintenance, advanced APM solutions make wind farms more efficient and cost-effective, contributing further to profitability, all while maintaining a high level of safety standards to safeguard both assets and personnel.

- Topics: APM, renewable energy, Wind

About Author