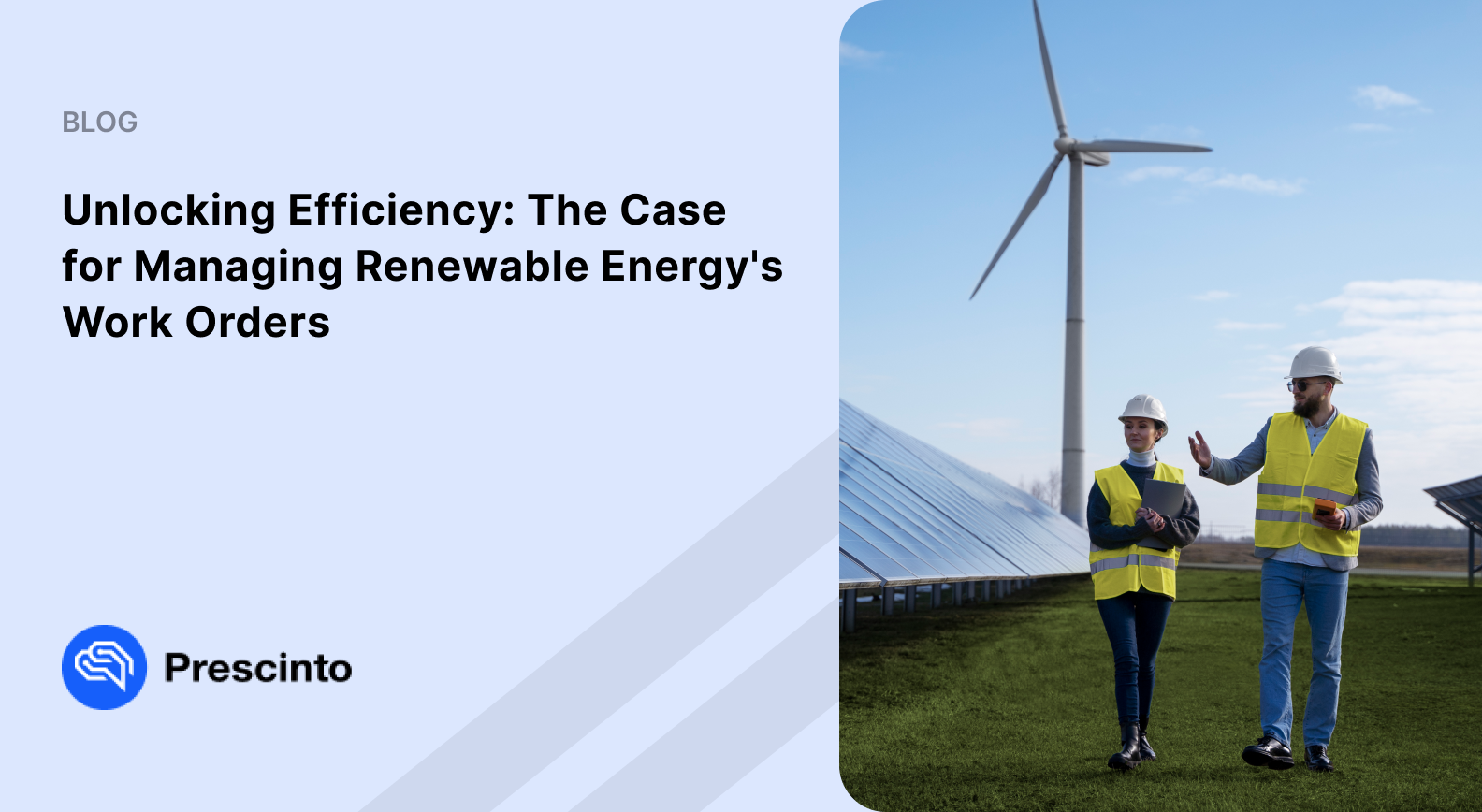

Unlocking the Power of Automated Cycle Detection for Battery Storage Systems

- September 20, 2023

- Prescinto

What is Automated Cycle Detection?

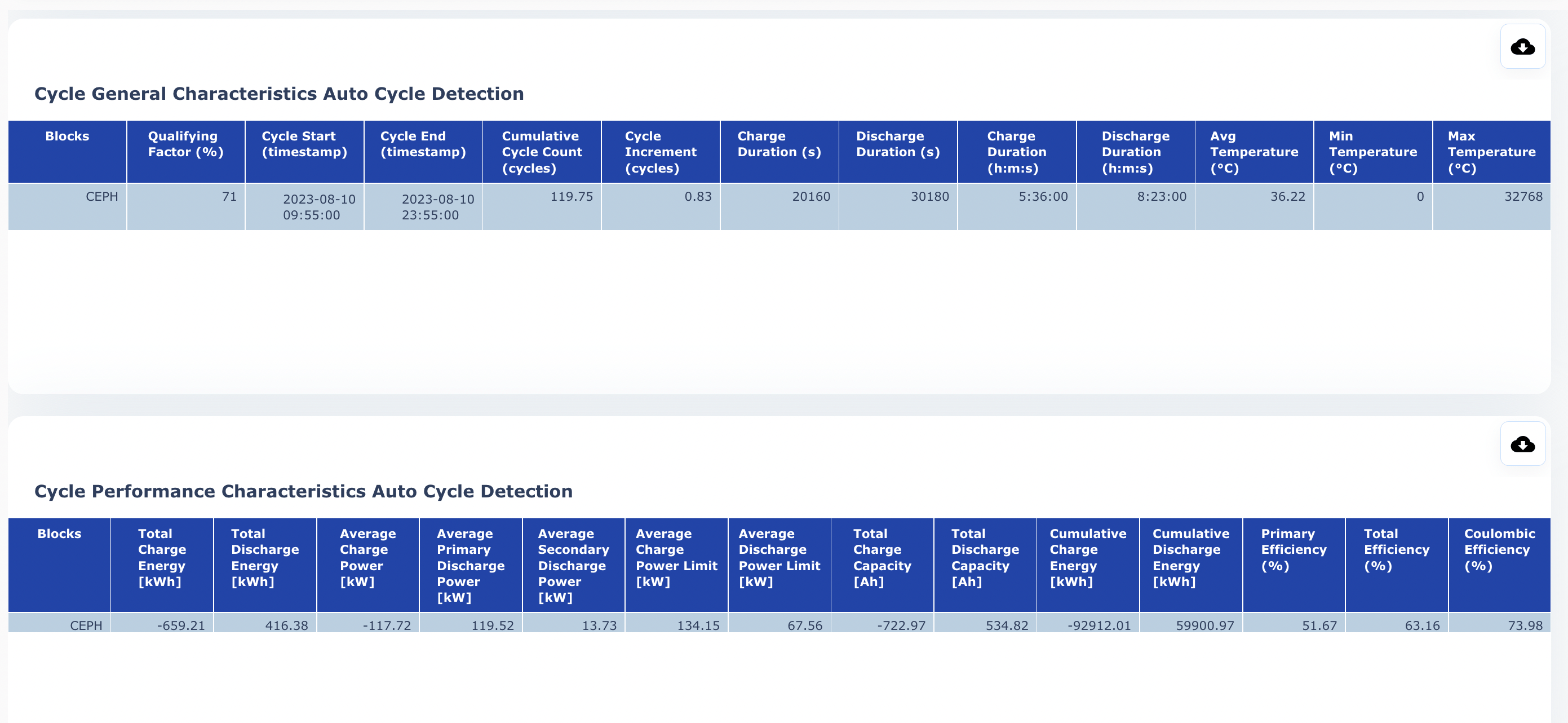

The Automated Cycle Detection feature in Prescinto is an advanced algorithm that is designed to recognize and identify a cycle from arbitrary battery operation. The focus of the algorithm is on defining a power profile that fully exercises the battery, making it useful as a metric of battery performance.

How does Automated Cycle Detection work?

The algorithm design is divided into two main parts:

- Definition of “Primary Discharge”: This refers to the period during discharge when the DC System is available at full power capacity for the direction of flow continuously from the start of discharge.

- Establishing Start and Stop Conditions: These conditions are used to bind the charge and primary discharge times. On charge, the timer accumulates while charging is occurring. On “primary discharge,” once the timer is started/stopped, further times when the start/stop conditions are met are ignored. The sequence forms a simple state machine, seeking conditions for Charge Start, then Charge End, then Primary Discharge Start, then Primary Discharge End, then Secondary Discharge End, and then looping around

The algorithm is designed to divide a battery cycle into several stages over the course of its charging and discharging. These stages are often useful for looking at the operation of the battery in order to determine whether a cycle is good for assessing the battery’s performance analytics. Qualifying cycles are those in which the battery is operated according to the cycle specification that defines how its performance is assessed. This means that the cycle includes a charge and discharge both at rated power and with minimal pauses.

The algorithm also includes several states for a better understanding of the battery’s performance:

- Boost: The initial stage where the battery voltage is brought above the minimum required level for the inverter or other power conversion equipment.

- Charge: The period when the battery is being charged. The algorithm monitors the charging current and if it is above a certain threshold for more than 30 seconds, the time is accumulated and considered as part of the charge period. If the charging current drops below the threshold for more than 30 seconds, the charge period is considered to be ended.

- Top of Charge: This stage is not implemented in the current algorithm. It would consider the time spent at the top of the charge level before moving to the next stage.

- Primary Discharge: The period when the battery is being discharged at its full power capacity. The algorithm monitors the discharge current and if it is above a certain threshold for more than 30 seconds, the time is accumulated and considered part of the primary discharge period.

- Secondary Discharge: The period when the battery is being discharged at a reduced power capacity.

- Rest: The final stage is where the battery is allowed to cool down and any leftover energy is exhausted before the next charge cycle begins.

The use of these states helps in identifying the overall performance of the battery and determining if it is operating according to the cycle specification. This feature is particularly useful for identifying underperforming batteries and taking appropriate action.

Benefits of Automated Cycle Detection Feature

-

Accurate recognition of cycles:

The algorithm is designed to accurately identify cycles from any battery operation, with a focus on creating a power profile that fully utilizes the battery to provide a reliable measure of battery performance.

-

Improved performance assessment:

By only qualifying cycles that are operated according to the cycle specification that defines how its performance is assessed, the algorithm provides a more accurate assessment of the battery’s performance.

-

Better understanding of battery operation:

The algorithm divides the battery cycle into several stages, which allows for a better understanding of the battery’s operation and how it is performing over time.

-

Reduced downtime and costs:

By identifying underperforming assets early and making necessary adjustments, automated cycle detection can help reduce downtime and costs.

Conclusion

Automated Cycle Detection is a powerful feature that enables power producers to unlock the true potential of their battery storage facilities. It simplifies the process of identifying and addressing underperformance issues, leading to improved performance and financial savings. The feature is easy to implement and can be customized to meet the specific needs of the facility. With Automated Cycle Detection, power producers can make data-driven decisions to improve the performance of their battery storage facilities, leading to improved bottom-line results.

- Topics: Energy Storage

About Author