Solar PV O&M: Performance and Cost Optimization Strategies

- March 9, 2024

- Prescinto

Solar PV O&M: Performance and Cost Optimization Strategies

Solar PV plants face various challenges, including unplanned downtime, equipment degradation over time, and suboptimal energy output due to inefficient maintenance. Irregular interruptions in solar energy generation and poor maintenance strategies can lead to reduced performance and increased financial losses, calling for solar O&M cost optimization.

Additionally, complexities of the system and adverse weather conditions impact the operations of solar plants. Given the high demand for solar energy generation to meet Net Zero obligations, operations and maintenance (O&M) becomes a mission-critical aspect to ensure the optimal performance to ensure the optimal performance of a solar PV plant.

But is O&M enough on its own? The simple answer is no! O&M, in its traditional manner, is not good enough, especially considering headwinds that O&M teams face. This is because of the increasing demand for solar PV generation and rising pressure to meet contractual obligations amid shortage of skilled workforce. Time has come that O&M teams adopt digitalization and use the right digital tools to their advantage.

O&M Expenditures in Solar PV Plants and How Does Digitization Impact These Cost Heads?

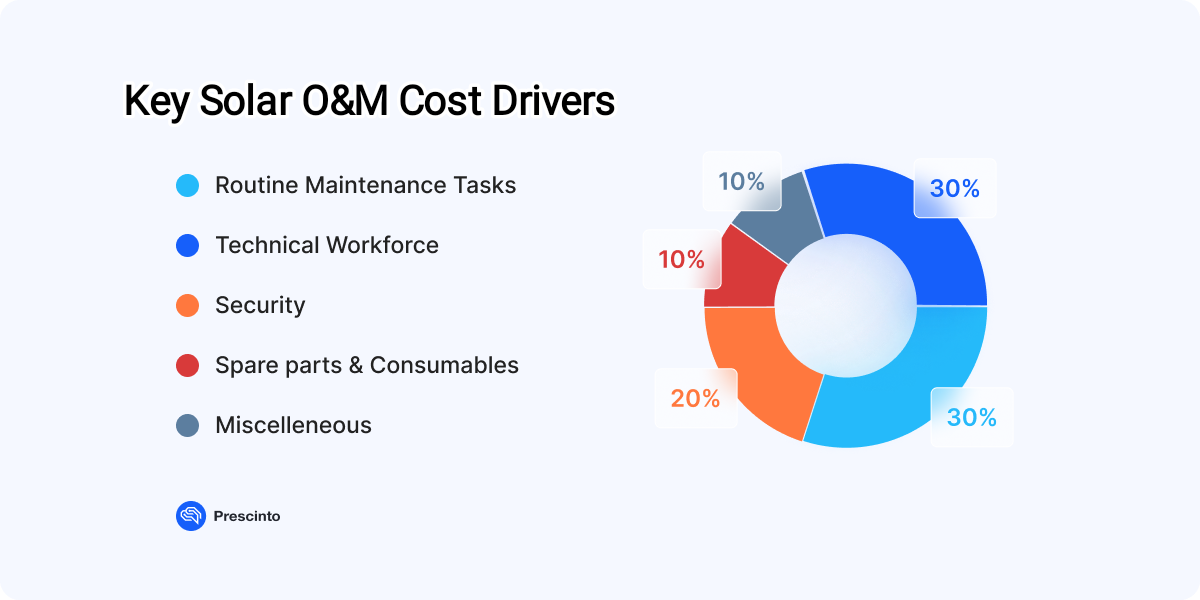

O&M expenses for solar PV plants cover everything needed to keep the system running smoothly. These expenses include technical team costs, routine maintenance costs, including module cleaning and grass cutting costs, monitoring systems, security costs, and inventory management costs. These costs are crucial for keeping the solar plant efficient and productive over time.

O&M service providers must focus on bringing down contract pricing, ensuring compliance to avoid security issues. They should make data-driven decisions in the best interest of their customers. Digitization positively impacts operations and maintenance (O&M) expenditures in solar PV plants by streamlining O&M tasks, boosting workforce productivity, ensuring regulatory compliance, optimizing inventory management, and improving profit margins. But that does not mean O&M teams take up rampant, thoughtless digitization. To get the right output from digitization, O&M teams must deploy the right digital tools that can deliver results!

Importance of OPEX Optimization for Solar PV Plants

O&M operators in renewable energy face financial risks like equipment failure, performance loss, and penalties related to penalties related to regulatory compliance. This can lead to huge financial losses for plant owners. A closer look at key cost drivers for O&M show that around 30% of expenses are related to technical manpower while another 30-35% goes to maintenance activities such as module cleaning, and grass cutting. O&M teams spend 18-20% on security, and another 5-15% on spare parts and consumables, depending on the plant’s age.

Lack of Skilled Technical Workers

In the Interstate Renewable Energy Council’s National Solar Jobs Census, 44% of solar industry employers in the US reported that it was “very difficult” to find qualified applicants, the highest percentage the census has ever recorded. It is evident that finding employees and laborers for solar plants has become a challenge. The workforce scenario is not very different in Europe either. Europe’s largest solar market, Germany, is predicted to lack 5 million workers by 2030, as reported by Reuters. Under these circumstances and considering the rapid expansion of installed solar capacities, large companies are actively seeking a skilled technical workforce for their operations and maintenance (O&M) needs. However, this high demand for skilled technical workers has led to increased costs in hiring and retaining such personnel.

Routine Maintenance Costs

The next cost component is routine maintenance. In the case of solar PV plants, conventional methods of panel cleaning call for a rigid approach, whereas a predetermined cleaning schedule requires O&M teams to clean solar panels around 18 to 24 times every year. In the US, most companies clean solar panels once a year, while the remaining don’t even bother to clean the panels. A study published on IEEE on utility-scale solar PV plants in North Carolina revealed a surprising impact: after seven years without solar panel cleaning, pollen buildup led to a whopping 15% drop in energy output during peak season. Despite rain, only a fraction of the pollen was removed, indicating a need for more effective cleaning methods.

On the flip side, overcleaning can also have detrimental effects. It not only proves ineffective but also results in financial losses and excessive wear and tear on the panels, ultimately reducing their lifespan and efficiency. In some solar PV installations, ‘solar grazing’ is implemented, letting animals graze solar farms. On a broad scale, solar grazing poses the risk of cable and equipment damage at sites. Understanding equipment and wiring failures on-time and taking remedial actions are critical, as they can lead to hazardous conditions and fire risks.

Inventory and Spare Parts Management

Inventory and spare parts management is yet another cost driver for solar O&M teams. During downtime, O&M teams often face the urgent need to purchase spare parts at high costs due to time constraints. This includes high transport and logistics costs associated with urgent deliveries. On the other hand, maintaining local on-site warehouses can lead to increased inventory management and holding costs, balancing the need for quick access to spare parts with cost-effectiveness.

Ensuring Compliance With Regulations

Ensuring compliance with labor laws and safety regulations is also a potential cost driver for solar O&M teams in the US, as noncompliance comes with hefty penalties. This includes adhering to annual electrical safety compliance requirements, maintaining accurate timelines, and keeping detailed observation sheets. Labor compliances play a significant role in workforce management and legal obligations. Many O&M teams face invoice delays due to issues, such as transit costs and insurance reimbursement claim delays, leading to outstanding dues. Tracking corrective maintenance hours and work orders for reimbursement is essential for financial transparency and efficiency.

Prescinto’s Digital Components to Effectively Optimize OPEX for Solar O&M

-

Utilizing Digital Twins for Solar Asset Modeling and Simulation

Utilizing digital twins for solar asset modeling and simulation enables operators to accurately predict performance, optimize maintenance planning, mitigate risks, enhance design and optimization, and improve training and decision-making. Solar O&M teams can leverage digital twin technology to make informed decisions about purchasing new equipment and optimizing existing ones. By creating virtual replicas of their solar PV plants, teams can simulate the performance of different equipment, such as inverters, under various conditions. This allows them to identify the most suitable equipment for their specific needs and operating conditions, ensuring optimal performance and efficiency.

Additionally, digital twins can be used to simulate the impact of equipment upgrades or modifications. This helps teams evaluate the potential benefits and costs before implementation. This data-driven approach helps minimize maintenance costs, while optimizing plant performance, leading to improved profit margins for solar O&M operations.

-

Implementing Drone Technology for Aerial Inspections and Data Collection

Implementing drone technology for aerial inspections and data collection in the solar energy industry offers significant benefits. Drones enable efficient data collection, enhance anomaly detection, optimize costs, improve safety, and boost scalability and competitiveness. By leveraging drones, solar PV companies can optimize performance, maximize energy generation, and stay competitive in the renewable energy market.

-

Real-Time Monitoring for Early Fault Detection and Proactive Maintenance

Asset Performance Management (APM) is vital for optimizing renewable energy assets like solar and wind farms. APM solutions with real-time monitoring, and maintenance planning help maximize returns on investments. Remote monitoring and analysis offers real-time data access and advanced analytics for early fault detection. This ensures cost savings, better decision-making, and enhanced customer satisfaction.

-

Automation of Routine Tasks to Improve Operational Efficiency

Automation is vital for efficiency in solar energy. It reduces manual work and errors while improving productivity. Key areas benefiting are monitoring, maintenance, data analysis, fault detection, remote operations, inventory, and reporting. Automation enables quick issue detection, remote management, optimized inventory, and regulatory compliance, boosting system performance and cutting costs.

Solar O&M Cost Optimization: How Prescinto Helps?

Implementing effective data management practices is essential for optimizing operational expenditure in renewable energy projects. By focusing on data quality and governance, organizations can ensure the accuracy and reliability of their data, enabling informed decision-making. Automated data quality checks and continuous monitoring help detect anomalies and inefficiencies, allowing for proactive interventions to improve asset performance and reduce downtime. Leveraging data-driven insights facilitates more efficient resource allocation and maintenance scheduling.

Data Governance Solution Baikal

Comprehensive data governance solution Baikal by Prescinto offers the necessary tools for data assessment, portfolio-wide visibility, trend analysis, and dynamic visualization. Baikal, helps its users determine the data quality and ensure that only meaningful data and not outliers are used for performance analytics and decision-making. Its advanced algorithms and automation capabilities allow for early detection of data-related issues, and its comprehensive view of data quality helps organizations to identify patterns and trends.

Leveraging Digital Twins and AI-Recommended O&M

Utilizing digital twins in solar power plants enables accurate performance prediction, optimized maintenance planning, risk mitigation, and enhanced decision-making. Solar O&M teams can simulate equipment performance, identify optimal solutions, and evaluate upgrades, ultimately minimizing costs and maximizing plant efficiency and profitability.

Tahoe, developed by Prescinto, is an AI-driven data analytics tool designed for solar power plants to identify and classify performance losses caused by various factors like soiling, clipping, and curtailment. It utilizes machine learning algorithms to provide real-time insights and accurately categorize losses into 14 distinct buckets. With Prescinto’s AI capabilities, solar O&M teams can prioritize critical tasks based on AI recommendations enabling them to prioritize remedial actions. Tahoe offers benefits such as efficient data analysis, determination of cleaning and rainfall efficacy, and ultimately helps optimize plant performance and increase ROI.

Asset Management with Drone and String Analytics

Combining drone analytics with string analytics, a unique feature of Prescinto, offers a powerful solution for efficient asset management in renewable energy projects. Drone analytics alone can identify defects in solar panels. But when integrated with string analysis, it goes further by quantifying the energy loss associated with each defect. This comprehensive approach enables proactive identification of issues like bypass diode failure, dirt/shadow, vegetation, hotspots, and more, leading to timely corrective actions and minimizing energy losses.

Additionally, Prescinto’s platform allows seamless integration with various drone vendors, ensuring flexibility and compatibility. With its end-to-end integrated process, from defect identification to generating work orders, Prescinto streamlines asset management, optimizing operational efficiency and maximizing energy generation.

Work Order Automation

By automating work orders, tasks such as preventative maintenance scheduling, equipment inspections, and repairs, O&M tasks can be efficiently managed without manual intervention. For maintenance managers, ensuring equipment’s smooth operations and efficiency is paramount. Additionally, automation allows for real-time tracking of work order status, providing visibility into ongoing tasks and facilitating better resource allocation. Work order automation in solar O&M helps streamline maintenance operations. It not only reduces manual effort, but also decreases mean time to repair (MTTR).

With Prescinto, O&M teams can manage and automate work orders with in-built CMMS. It is an integrated platform to manage and track all types of work orders, ensure contractual compliance, optimize availability, and safety of asset management. The automatic work order management feature in the Prescinto Platform plays a crucial role. Users get to set specific conditions and thresholds. The platform can generate work orders from custom alerts, alarms, and warnings from field devices, seamlessly mapping them to corresponding issues.

Implementing Real-Time Monitoring to Identify and Address Issues Promptly

Implementing real-time monitoring is essential for swiftly identifying and addressing issues in renewable energy assets. Prescinto allows for multiple levels of customization – from custom dashboards to custom reports and KPI tracking. In addition, the Flexi Widget feature on the Prescinto platform offers users a high level of customization for dashboards. This allows the selection of specific charts and data relevant to the industry. Solar asset managers and O&M teams can easily access and monitor critical metrics such as Specific Yield, Generation, and Performance Ratio in a format that suits their needs. The platform also provides heatmap charts, enabling users to visualize data points and trends effectively.

Additionally, features like Daily Generation Comparison allow for quick analysis of daily generation trends. Time Series Generation Data provides a detailed view of generation data over time. Prescinto also offers Map View, which offers an intuitive visualization of all plants with portfolio summaries and much more. Prescinto’s AI-powered platform integrates advanced analytics, automation, and IoT technologies for efficient monitoring.

Importance of Adopting a Holistic APM Strategy for O&M Expenditure Reduction in Solar Plants

A holistic APM strategy for O&M in solar PV plants involves integrating various aspects of asset management to improve performance and optimize OPEX. This includes data integration from various sources, continuous performance monitoring, resource optimization, and automation of routine tasks. Creation of digital twins allow for simulation and optimization. O&M teams must also utilize advanced analytics for insights, and leverage an end-to-end platform that integrates with ERP and BI systems for streamlined operations and decision-making.

By leveraging advanced technologies for O&M field services, service providers can break down information silos and gain real-time visibility into the status of all field work and resources. This visibility enables informed decision-making and effective O&M cost optimization, especially when faced with multiple equipment outages and limited resources.

About Author