Strategic Insights: Enhancing O&M Performance with Data Centralization in Renewable Energy

- March 11, 2024

- prescinto

Data is the new oil! Nowadays, it is ubiquitous to see industrial systems and infrastructure becoming more complex, thereby making operations and maintenance (O&M) more challenging. Even the progressing renewable energy sector is no stranger to this. Under the stringent performance demands from renewable asset owners, O&M operators are brought to the spotlight to revisit the decision-making of their control processes. Many leading O&M players are revisiting their Remote Operations Center (ROC) process to manage growth and complexity. Sensors, equipment, procedures, and workflows throughout these facilities create vast volumes of data. However, all this data from globally distributed assets is frequently stored in various systems and walled databases. Thus, making it difficult to obtain a consolidated perspective and extract insights. IT and businesses should be strategically aligned. One such IT strategy is data centralization- the essential step to power ROC operations.

What is Data Centralization for O&M?

Data centralization is the practice of collecting all the company’s data into an enterprise database, a data warehouse, or a data lake as raw data. This centralized repository becomes the company’s exclusive source of truth.

Data centralization involves gathering real-time data from sensors, SCADA systems, PLC, data loggers, historical data, plant budget and forecast data, asset masters, and assent maintenance history from data lakes. The objective is to streamline data integration and provide a single picture. That implies an analyzable data warehouse, to streamline O&M activities and improve energy availability.

Data Centralization Challenges Faced by O&M Providers

Due to the expanding number of renewable assets, O&M organizations now have dispersed data across diverse systems and formats, across the globe. This results in isolated “silos” that impede visibility and informed decision-making. Likewise, other prevalent issues in the renewable energy industry, the primary obstacles encountered in O&M:

- Prominent usage of low automated technology maintenance approaches renders the industrial environment vulnerable to unforeseen difficulties and rising operating expenses.

- Poorly centralized data regarding the industrial process and the usage of dispersed task management systems result in a significant loss of knowledge over time.

- Lack of visibility into Plant performance and operations for central teams. This challenge gets magnified with the scale of operations.

- Difficulty in analyzing the vast amount of information arriving at various velocities and presented in multiple disparate spreadsheets.

- Difficulty in spotting problems, as well as making agile strategic decisions, resulting in unwarranted downtime.

- Limited budget to deal with the challenges presented in the industrial plant.

Why is Data Centralization Crucial for O&M?

In the renewable sector, data is the fuel for optimizing performance, boosting efficiency, and accelerating the transition to a sustainable future. For many years, O&M data has been scattered across distinct operational and information technology (OT/IT) systems. According to Energy Global, the recovery times during a single day of downtime can cost the organization more than USD 1 million in lost revenue.

Moreover, precious information is trapped, and integrated data is necessary to provide prescriptive and predictive insights that improve O&M planning. Lack of centralized data translates into blind spots in asset health and performance. This translates to more reactive maintenance and missed-out insightful opportunities for efficiency. To reduce such outcomes and to enable ROC operations, implementing data centralization is vital. It creates the framework for a unified data architecture that can handle advanced analytics.

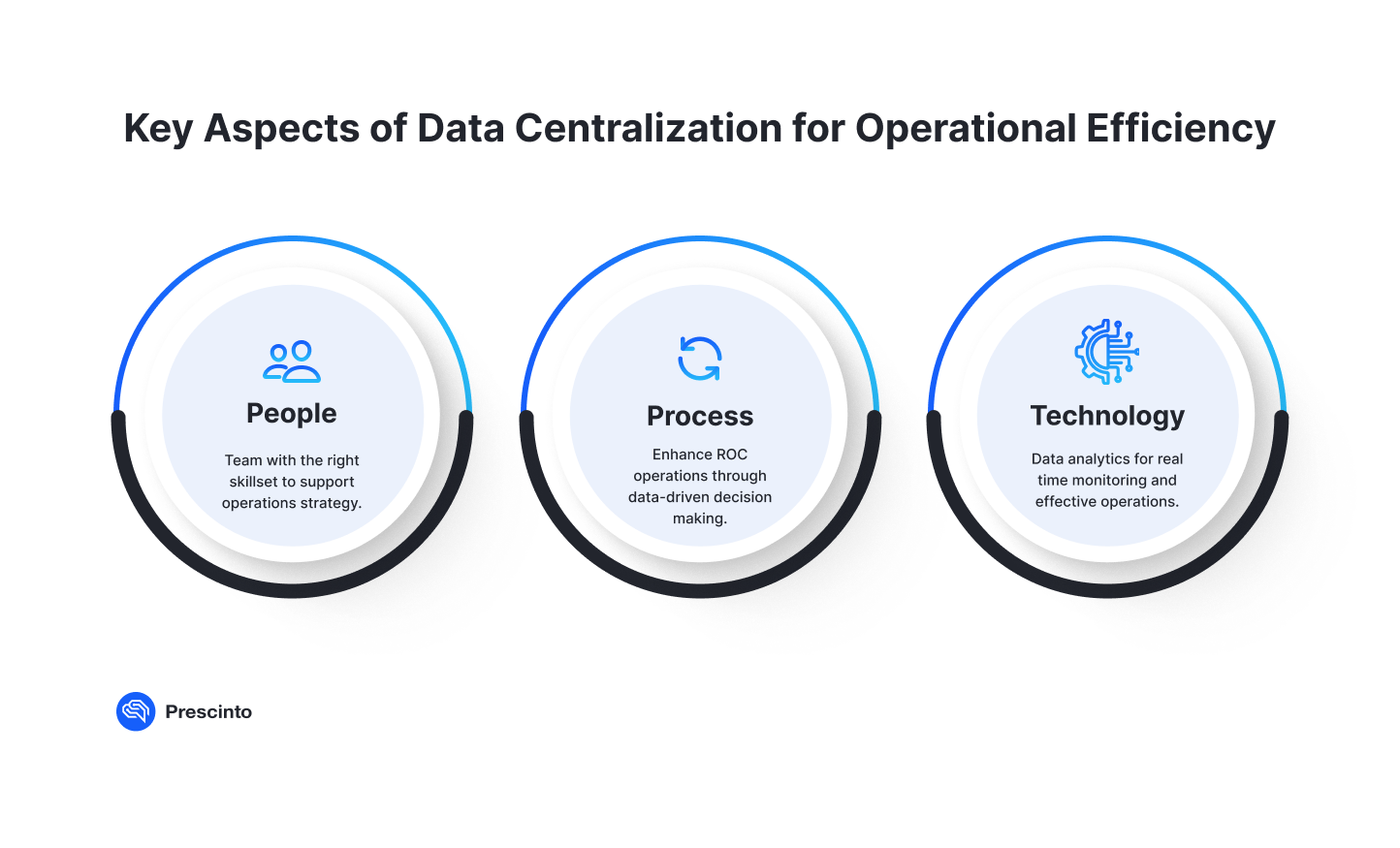

Key Aspects of Data Centralization for Operational Efficiency

Data centralization plays a critical role in the digital transformation of O&M for renewable energy assets. It has significant impacts on the three key pillars of O&M – people, process, and technology.

Some of the main reasons why data centralization is vital for O&M:

- System Integration: Data centralization combines signal data from all devices, SCADA, loggers, asset data, work order history, inventory, dependability metrics, operating circumstances, and maintenance charges on a single platform. It can track key performance indicators (KPIs) in real-time, detect abnormalities early on, and make educated decisions before situations worsen.

- Lower Costs: It can reduce downtime, failures, inventory holdings, and labor hours, which in turn can considerably cut costs.

- Faster Root Cause Analysis: Cross-referencing real-time and historical data speeds up failure identification.

- Predictive and Condition-based Maintenance: It provides the base to use historical data, present data, and advanced analytics for maintenance to prevent probable breakdowns. Preventative maintenance reduces downtime and increases asset lifespan, avoiding costly reactive repairs. As a result, maintenance techniques are being optimized to maximize asset reliability.

- Optimized Resource Allocation: O&M providers can learn about asset utilization and performance throughout their portfolio. Moreover, they can allocate resources effectively, prioritize main assets, and maximize return on investment.

5 Crucial Challenges in Data Centralization

Despite its potential, data centralization faces hurdles in the renewable energy sector:

- Data Silos: Different equipment suppliers and systems use different data formats and communication protocols, resulting in isolated pockets of information. Unifying these silos needs seamless integration solutions.

- Standardization: Inconsistent data formats, units, and language across projects and device types impede thorough analysis and comparison. Industry-wide standardization initiatives are underway.

- Data Quality and Governance: To ensure data correctness, completeness, and security, well-built data governance procedures must be implemented. Poor data governance practices lead to a decrease in trust in the system data, as there will be multiple instances of data silos, data obsolescence, and data sprawling.

- Limited Knowledge: Access to experienced professionals with data analytics and management knowledge may be limited. As a result, efficient data utilization is reduced.

- Legacy Infrastructure: Integrating current infrastructure with new data centralization technologies can be expensive and time-consuming, necessitating a staged strategy.

Take Control of Your Assets with Prescinto’s Asset Performance Management (APM)

Managing various assets across renewable energy projects may be daunting. Juggling maintenance plans, tracking performance, and maintaining maximum efficiency translates into a full-time job.

Prescinto understands the intricate issues encountered by asset managers and O&M providers. Prescinto’s end-to-end Asset Performance Management (APM) is a comprehensive suite of technologies and tools that aim to improve asset performance and O&M efficiency across equipment and plants. Prescinto’s unique data governance module, Baikal, provides value to solar, wind, and energy storage systems by monitoring data availability, removing data defects, and providing accurate performance analytics.

Data Centralization using CMMS Master

Prescinto’s APM contains a Computerized Maintenance Management System (CMMS) Master can create a comprehensive database of your assets, maintenance schedules, and team members. Access all the information you need in one central location. Other features of the service include:

- Simplify Work Order Management: Prescinto’s CMMS aids in generating work orders automatically for preventive and corrective maintenance tasks based on the information you updated in the CMMS master, triggered by instant emails or SMS alerts from our monitoring tools or directly from the map or drone view. Schedule bulk-automate recurring maintenance tasks in advance for all your assets, ensuring timely intervention and preventing downtime.

- Boost Efficiency and Save Time: CMMS Master can help you manage your spare parts and materials seamlessly within the platform, eliminating the need for separate systems. The platform offers insightful dashboards to optimize ROC operations alongside customizable automatic reporting and scheduling.

- Cut Down Your Workload, Increase Your Performance: Prescinto enables you to save at least half the time spent on data collating and matching and data preparation for analysis and operational tasks, freeing up your time for strategic decision-making. Other plus points include achieving improvement in asset performance with condition-based maintenance and data-driven insights as well as reducing reporting time from 24 hours per week to less than 1 hour per week with our automatic report generation.

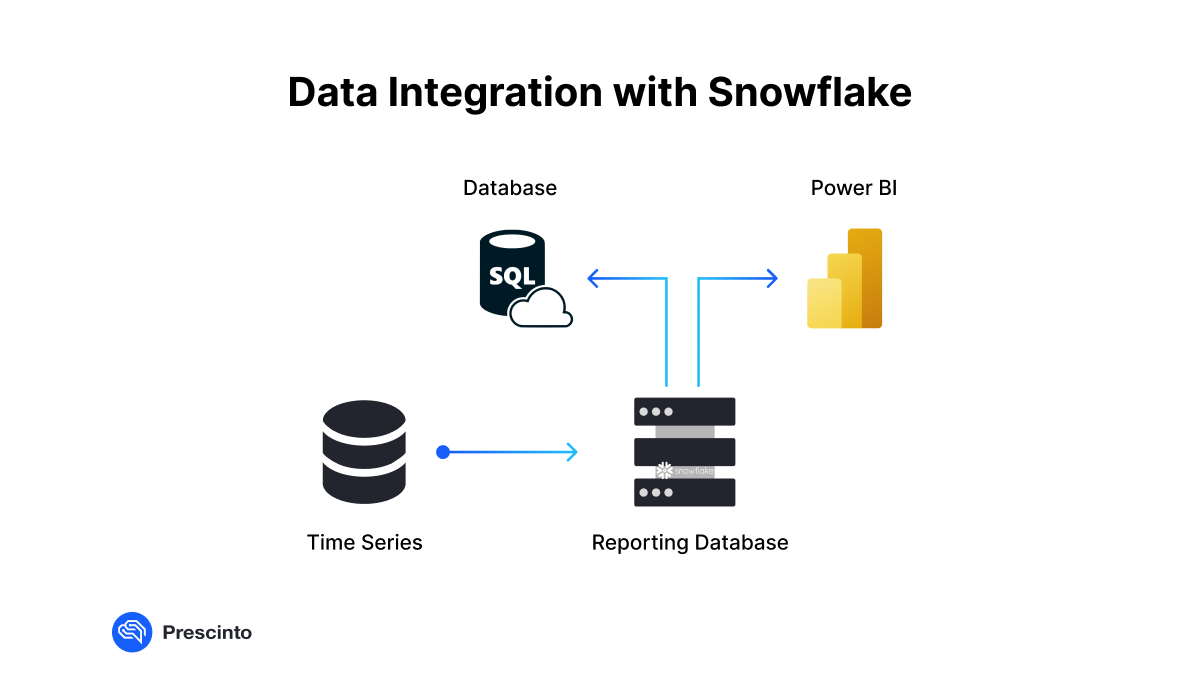

Data Centralization using Snowflake

Prescinto’s Snowflake is a data warehouse, with native integration to Power BI, that provides seamless data integration to external systems like ERP systems for streamlined operations. It connects disparate data sources, such as CMMS, field devices, SCADA, APIs, loggers, and files. It can break down silos and ensure comprehensive data capture for time series data with the comfort of your own Power BI tools. Thus, bending the data based on your needs. This service provides dynamic scalability and secure storage to manage your data, regardless of volume or complexity to produce automated reports. Moreover, its integration with Power BI enhances data visualization.

Conclusion

Data is the fuel powering next-gen O&M strategies. Centralizing this mission-critical asset enables organizations to sustain asset availability, minimize costs, and de-risk operations. However, technology is only an enabler. By harnessing the power of its data, Prescinto can not only achieve optimal performance and cost-efficiency but also contribute significantly to a more sustainable and environmentally conscious future. In the end, centralized O&M data represents potential – potential to be unlocked through imagination.

- Topics: APM, Data Centralization, O&M

About Author